The evolution of automatic dispensers within the decorative coatings market is well documented. In the UK and across Europe, automatic tinting machines have been commonplace now for many years. From the early days of Monomatics and Omnimatics, now rendered obsolete by the 16 universal and water based colorant systems offered by the major colorant producers, to the latest innovations relating to pump technology and software control systems, dispensers have become more sophisticated, highly accurate even with the most nominal dispense volumes and reliable. Although the US has lagged Europe in terms of the adoption of automated systems, having been the pioneers of tinting and the widespread use of tinting machines, they too are now moving ahead and going auto.

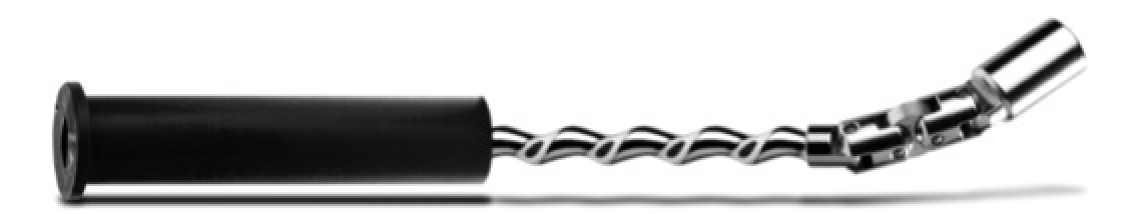

However, the same cannot be said for many sectors of the coatings industry. Many companies active in the automotive, industrial, marine and specialist coatings sectors have yet to make the switch to auto. Some may say it takes a ‘leap of faith' to switch from a tried and trusted way of operating into a new arena. The truth is that the benefits are significant. HERO's patented PCP (Progressive Cavity Pump) technology is extremely versatile, competently and reliably handling even the most challenging colorants and components in coatings formulations used across most sectors of the coatings industry.

PCP technology, coupled with HERO's Tintwise software can give coatings specialists in sectors from automotive to woodcare a leading edge over their competitors in terms of flexibility, efficiency and speed of dispensing and mixing products. With the widest selection of automatic dispensers, from entry level ‘POS' machines to in-can/plant dosing systems, HERO have a machine to suit your demands. And when you're using expensive colorants and base materials, automation avoids user errors and expensive mistakes.

To learn more about what HERO have to offer and how we can tailor a tinting solution to suit your needs, contact Colour Genie.